Imagine waking up each morning, nestled among thousands of bushels of corn, wheat, or soybeans. That’s life in the grain bin — your in-bin cable sensors speaking! We’re the unsung heroes of your grain-conditioning strategy, tirelessly measuring temperature and moisture to keep your investment safe and sound. Pull up a chair, and we’ll tell you how we monitor every fluctuation, from the depths of the bin to the very top.

When dawn breaks, your grain isn’t just a silent mass. It’s a living system, reacting to changes in weather, airflow, and even the heat generated by its own mass. That’s where we come in:

- Temperature Monitoring

We’re spread out vertically along our sturdy cables, each of us recording the bin’s internal temperature every few minutes. When ambient air cools overnight, we detect cold spots. If one area drops below your set threshold, we flag it immediately—so your fans can be fired up for optimal grain conditioning before frost damage begins. - Moisture Detection

Grain moisture levels shift more subtly but can wreak havoc if left unchecked. We sample moisture at each sensor node, watching for any rise that might signal mold growth. A single percentage point increase in one spot can spell trouble, so we send an alert at the first sign of trouble.

Fluctuations Don’t Stand a Chance

Let’s talk about real‑world drama! Imagine a warm spring day where afternoon heat spikes inside the bin. The bottom layers stay cool, but the top 20 feet warms rapidly:

- Early Morning: Temperatures are uniform at about 60°F. Moisture readings hover around 13%.

- Midday Heat: The top sensors climb to 75°F while the bottom stays at 62°F. Our moisture nodes at the top register a slight dip—grain dries faster in warm air.

- Twilight Chill: As the sun sets, a cold front rolls in. Temperatures at the top plunge to 55°F, while the bottom holds at 65°F. When we see that cold air sinking, we trigger your aeration fans to mix the profile back into your ideal envelope.

This continuous feedback loop ensures that every pocket of your bin stays within ideal limits for both temperature and moisture, preventing spoilage, maintaining quality, and protecting your bottom line.

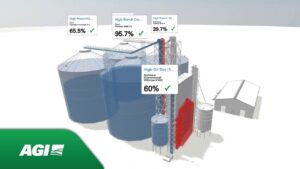

Integrating with AGI SureTrack

We’re more than standalone sensors; we’re part of the smart ecosystem powered by AGI SureTrack. Here’s how that connection elevates your grain management:

- Real‑Time Alerts: Through the SureTrack dashboard, we push instant notifications to your phone or desktop whenever readings deviate from your ideal range.

- Historical Trends: Every data point we collect gets logged, letting you review past seasons and refine your grain conditioning schedules.

- Automated Controls: Pair us with automated fan controllers, and we’ll activate aeration or drying sequences based on our measurements—no manual intervention needed.

Why You’ll Love Our Story

By listening to our continuous chatter, you become a proactive grain manager. You’ll:

- Reduce Risk: Early detection of hotspots and moisture pockets prevents costly mold outbreaks.

- Optimize Drying: Fine‑tune your drying process by understanding exactly when and where grain needs attention.

- Save Energy: Only run fans or dryers when necessary — data‑driven decisions mean lower utility bills.

- Ensure Quality: Consistent conditions preserve test weight, germination rates, and end‐use performance.

We are Your In‑Bin Companions

From the first bushel to the final load out, we stand guard—your network of grain temperature and moisture sensors. In partnership with Valley View Agri‑Systems and the AGI SureTrack platform, we ensure every fluctuation becomes an opportunity rather than a liability. Together, we make grain conditioning smarter, safer, and more efficient than ever before.

So next time you check your SureTrack dashboard, remember it’s not just numbers you see. It’s our story of steady vigilance, speaking up whenever conditions shift—so you can rest easy, harvest after harvest. Contact Valley View Agri-Systems to get more of our story.