Grain spoilage in storage is one of the most frustrating and costly challenges a producer can face. Whether you’re running a small family farm or managing a large-scale grain operation, keeping your harvested crop in top condition is critical to protecting your investment.

At Valley View Agri-Systems, we’ve seen the consequences of grain spoilage—and we’ve helped countless producers avoid it. Let’s take a closer look at what causes grain spoilage, how to prevent it, and what to do if it starts to happen in your bin.

What Causes Grain Spoilage?

Grain spoilage usually starts with excess moisture or poor temperature control in the bin. Warm, damp conditions create the perfect environment for mold, fungi, and insect infestations to thrive. If left unchecked, these issues can quickly reduce the quality of your grain—sometimes making it completely unsellable.

Some early warning signs of spoilage include:

- A sour or musty smell in or around the bin

- Condensation on the roof or bin walls

- Hot spots or uneven temperatures

- Clumped or crusted grain that doesn’t flow freely

In addition to lost revenue, spoiled grain can pose serious safety risks. Moldy grain can be harmful to breathe and crusted or bridged grain can lead to bin collapses or entrapments.

How to Prevent Spoilage

The good news is that with the right tools and practices, grain spoilage is largely preventable. Here are some of the key ways to protect your stored grain:

1. Proper Grain Conditioning

Grain conditioning is the process of managing grain temperature and moisture levels before and during storage. It starts with drying your grain to the correct moisture content and continues with ongoing cooling and aeration.

A well-conditioned grain bin will reduce the risk of moisture migration and temperature fluctuations—two of the biggest contributors to spoilage. Even a few degrees of extra warmth in a bin can lead to big problems if left unaddressed.

2. Use of Aeration and Ventilation

After drying, aeration fans help keep the grain cool and evenly conditioned. Running fans regularly helps prevent the warm and cold spots that encourage mold and insect growth. Even during the colder months, it’s important to monitor and manage airflow to avoid condensation and humidity buildup inside the bin.

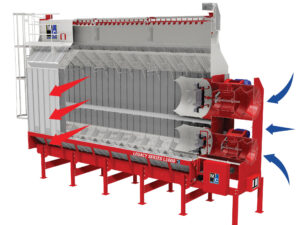

3. Advanced Grain Systems

Modern grain systems often include monitoring technology that allows you to track conditions inside the bin in real-time. These advanced systems can alert you to rising temperatures or humidity levels, giving you the opportunity to act before spoilage takes hold.

Temperature cables, moisture sensors, and automated fan controls are valuable tools that help ensure your grain stays in ideal condition throughout the storage period.

4. Portable Grain Dryers

A portable grain dryer can be a game-changer during harvest or when dealing with pockets of high-moisture grain. These flexible systems allow you to target problem areas and dry grain to a safe level before it goes into long-term storage. By removing excess moisture early, you reduce the risk of spoilage significantly.

What to Do If Spoilage Starts

Even with the best equipment and intentions, spoilage can still occur—especially during warm, wet seasons or if grain goes into the bin with too much moisture.

If you suspect spoilage:

- Run your aeration fans to cool the grain and dry out damp areas.

- Check for clumping or crusting near the top center of the bin.

- If needed, break up and remove spoiled sections from the top down.

- Monitor conditions closely and consider moving grain to another bin or drying again if the issue persists.

Most importantly—act fast. The longer you wait, the more the problem spreads.

How Valley View Agri-Systems Can Help

At Valley View Agri-Systems, we specialize in helping producers build and maintain reliable grain storage systems. From grain conditioning equipment and portable grain dryers to advanced grain systems and aeration solutions, we offer the tools and expertise you need to keep your grain safe and profitable.

Whether you’re designing a new bin site or upgrading an existing one, our team is here to help you choose the right solutions for your operation. We understand how grain systems work—because we’ve built and serviced them for decades.

Let us help you protect your grain—and your bottom line.

Contact Valley View Agri-Systems today to learn how we can support your storage goals and keep spoilage out of your bins.